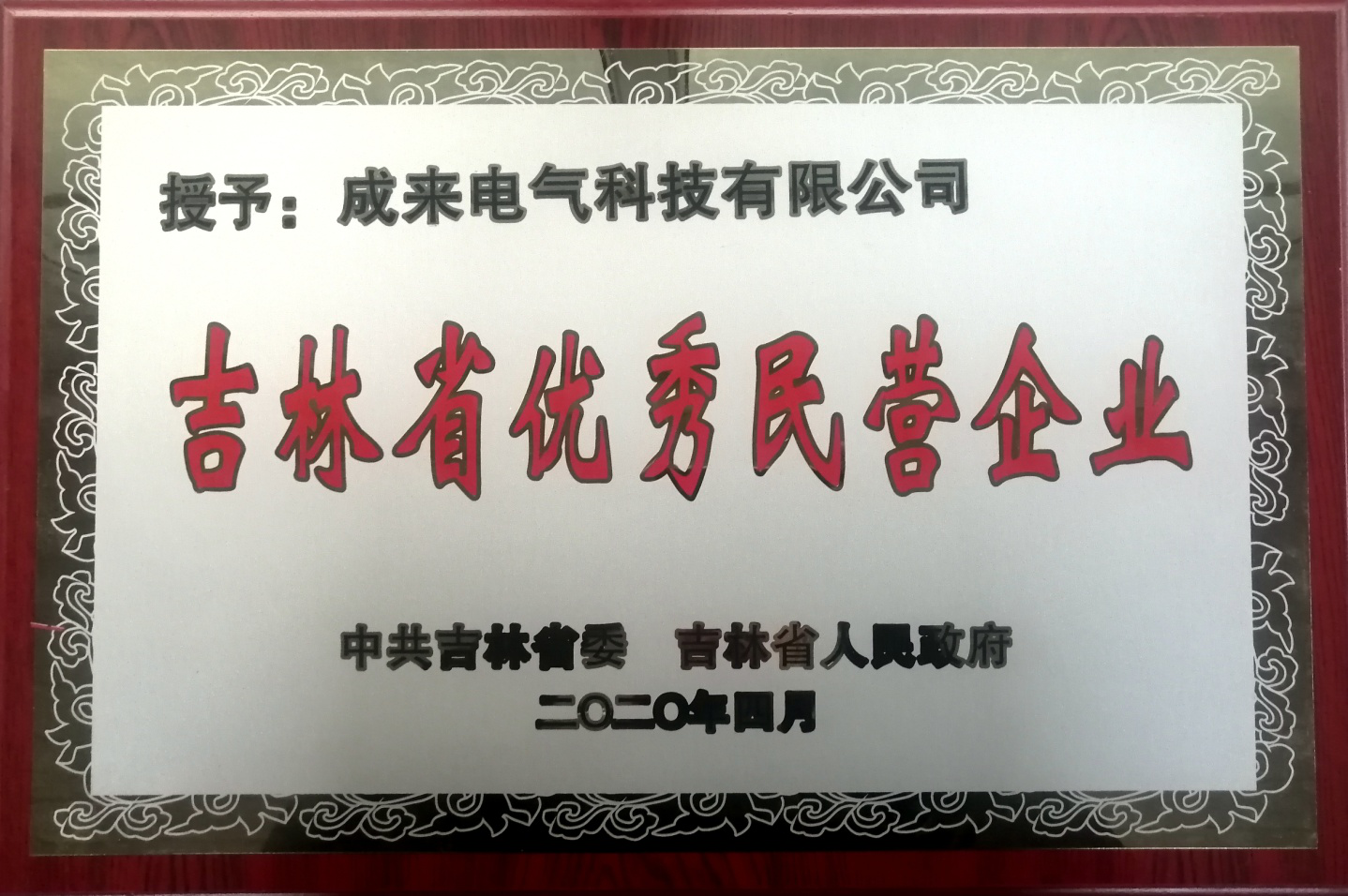

Chenglai Electric Technology Co., Ltd. was rated as an outstanding private enterprise in Jilin Province

- Categories:company news

- Author:

- Origin:

- Time of issue:2020-11-05

- Views:0

(Summary description)Chenglai Electric Technology Co., Ltd. has always been committed to becoming a first-class supplier in the field of power transmission and transformation equipment and building a "100-year-old Chenglai" brand. Since its establishment 50 years ago, under the guidance of government departments at all levels, in line with the spirit of defying difficulties, pioneering and innovating, serving the society, it has become a leading enterprise in the industry in our county. Its business performance ranks in the forefront of the country. Lai Electric Technology Co., Ltd. was rated as outstanding private enterprise in Jilin Province.

Chenglai Electric Technology Co., Ltd. was rated as an outstanding private enterprise in Jilin Province

(Summary description)Chenglai Electric Technology Co., Ltd. has always been committed to becoming a first-class supplier in the field of power transmission and transformation equipment and building a "100-year-old Chenglai" brand. Since its establishment 50 years ago, under the guidance of government departments at all levels, in line with the spirit of defying difficulties, pioneering and innovating, serving the society, it has become a leading enterprise in the industry in our county. Its business performance ranks in the forefront of the country. Lai Electric Technology Co., Ltd. was rated as outstanding private enterprise in Jilin Province.

- Categories:company news

- Author:

- Origin:

- Time of issue:2020-11-05

- Views:0

Chenglai Electric Technology Co., Ltd. has always been committed to becoming a first-class supplier in the field of power transmission and transformation equipment and building a "100-year-old Chenglai" brand. Since its establishment 50 years ago, under the guidance of government departments at all levels, in line with the spirit of defying difficulties, pioneering and innovating, serving the society, it has become a leading enterprise in the industry in our county. Its business performance ranks in the forefront of the country. Lai Electric Technology Co., Ltd. was rated as outstanding private enterprise in Jilin Province.

Scan the QR code to read on your phone

Mobile station

More exciting waiting for you!

Copyright © 2021 Chenglai Electric Technology Co., Ltd. 吉ICP备16001082号