Partner

- Categories:Customer Show

- Author:Chenglai Electric Technology Co., Ltd.

- Origin:http://www.cl-dq.com/

- Time of issue:2021-03-12

- Views:0

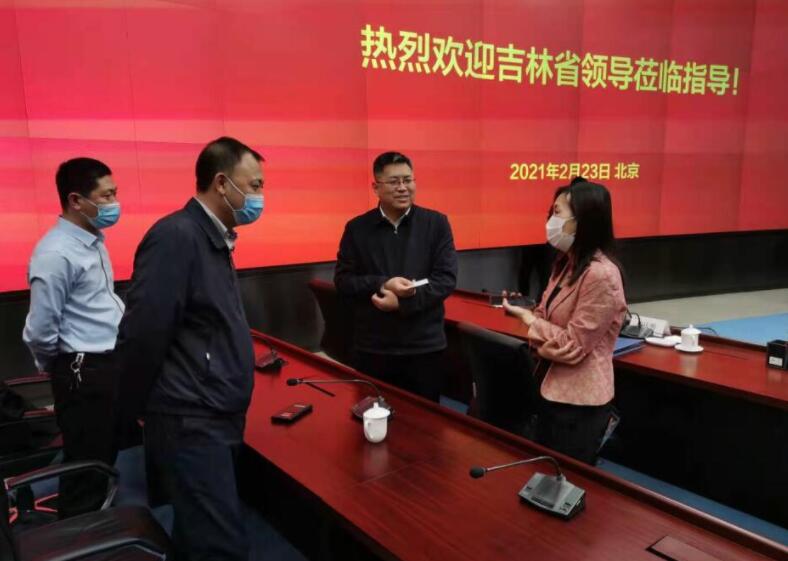

(Summary description)Chairman Wang Xiquan accompanied Vice Governor Li Wei and Vice Mayor Zhang Tianhua to Beijing to visit Sanxia New Energy Co., Ltd.

Negotiate cooperation work plan

In order to further deepen the cooperation between the central and local governments and improve the effectiveness of the investment promotion activities of central enterprises in helping Jilin revitalize and develop, on February 23, Vice Governor Li Wei, Deputy Mayor Zhang Tianhua, and Chairman Wang Xiquan went to Beijing to visit Vice President Liu Zi of Three Gorges New Energy Co., Ltd. Manager, started the docking of key cooperation projects between Three Gorges New Energy Co., Ltd. and Chenglai Electric Technology Co., Ltd.

Partner

(Summary description)Chairman Wang Xiquan accompanied Vice Governor Li Wei and Vice Mayor Zhang Tianhua to Beijing to visit Sanxia New Energy Co., Ltd.

Negotiate cooperation work plan

In order to further deepen the cooperation between the central and local governments and improve the effectiveness of the investment promotion activities of central enterprises in helping Jilin revitalize and develop, on February 23, Vice Governor Li Wei, Deputy Mayor Zhang Tianhua, and Chairman Wang Xiquan went to Beijing to visit Vice President Liu Zi of Three Gorges New Energy Co., Ltd. Manager, started the docking of key cooperation projects between Three Gorges New Energy Co., Ltd. and Chenglai Electric Technology Co., Ltd.

- Categories:Customer Show

- Author:Chenglai Electric Technology Co., Ltd.

- Origin:http://www.cl-dq.com/

- Time of issue:2021-03-12

- Views:0

Chairman Wang Xiquan accompanied Vice Governor Li Wei and Vice Mayor Zhang Tianhua to Beijing to visit Sanxia New Energy Co., Ltd.

Negotiate cooperation work plan

In order to further deepen the cooperation between the central and local governments and improve the effectiveness of the investment promotion activities of central enterprises in helping Jilin revitalize and develop, on February 23, Vice Governor Li Wei, Deputy Mayor Zhang Tianhua, and Chairman Wang Xiquan went to Beijing to visit Vice President Liu Zi of Three Gorges New Energy Co., Ltd. Manager, started the docking of key cooperation projects between Three Gorges New Energy Co., Ltd. and Chenglai Electric Technology Co., Ltd.

Scan the QR code to read on your phone

Mobile station

More exciting waiting for you!

Copyright © 2021 Chenglai Electric Technology Co., Ltd. 吉ICP备16001082号